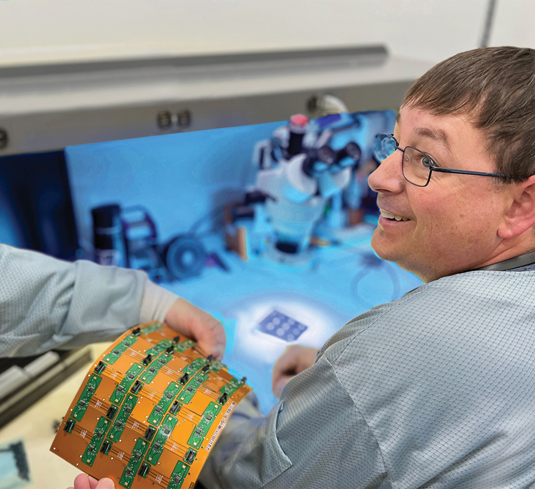

While we welcome your questions regarding our equipment list, we believe quality contract electronic manufacturing is our hallmark.

Our adherence to our own quality standards is a commitment that is deeply embedded in our culture. With quality as our foundation, we are most likely to create value in electronics manufacturing. Westshore quality management system (QMS) is comprised of well-defined corporate-wide processes focused on meeting customer requirements on established metrics aligned with organizational values and strategic goals. Our 6-Point QMS Program includes:

Quality Electronics

Westshore will strive to exceed our customer’s expectations by providing best-in-class electro-mechanical solutions. We will contribute to our customer’s success by continually improving, delivering products on time, and with the very best quality.

The Right People | The Right Training

Engineering and project management are vital to quality control in electronic manufacturing. Westshore staff is among the best; experienced in understanding client needs, developing solutions, and remaining responsible for your project at every stage. Westshore will strive to exceed our customer’s expectations by providing best-in-class electro-mechanical solutions. Westshore offers on-site IPC training for its employees to ensure all are trained to the latest technology and standards.

Risk Management

Westshore risk mitigation program helps keep liabilities at a minimum by identifying and resolving any potential issues before they impact the entire manufacturing process. We will contribute to our customer’s success by continually improving, delivering products on time, and with the very best quality. We achieve this by using tools such as PFMEA, Pilot Process, PPAP, FAI, 8D, 5 Why and Fish Bone technics.

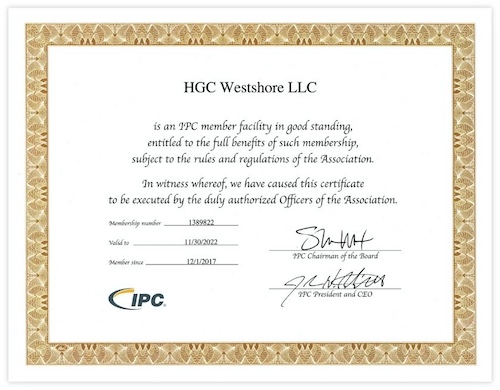

IPC Inspection

Westshore manufacturers components that adhere to IPC production standards for Acceptance Quality Level (AQL). The AQL number determines whether an electronic component has rejections that classify it as substandard.

TTC System

The Track, Trace, and Control System regulates manufacturing methods, stabilizes elements, oversees components, collects statistics, and record human operated activities for statistical issues.

First Article Approval

Our engineers test the first product used in customers production outside our manufacturing facility, assuring electronic quality control prior to batch approval.

Certifications